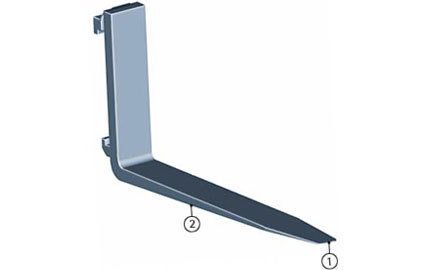

Pin-type (shaft-mounted) Quality Forks

Pin-Type forks are guided on a shaft.

The dimensions are not standardized. SINOLIFT is producing a wide variety of pin-type forks which are individually designed to customer's requirement.

Mostly pin-type forks are used for larger lift trucks or for construction machines.

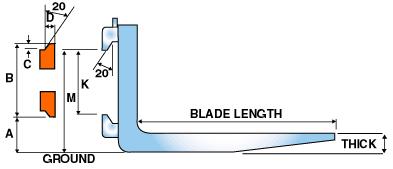

Fully tappered quality forks

Forks with a long taper on the lower side of the blade. Basically, the taper starts close to the heel. The fork is shaped like a knife and is often just a few mm thick.

Fully tapered forks are tailor-made to suit customers' requirements in terms of fork thickness, tip thickness and taper length. Fully tapered forks are mostly used in the furniture and wood panel industries.

To quote the following additional data is required:

1. Tip thickness (mm);

2. Length of taper.

| Class

| Width(in. ) |

Tickness(in. ) |

Capacity(T/pair) |

Safe Working Mark(kg*mm) |

Length(in. ) |

Item No. |

| Ⅱ |

4(100) |

1.38(35) |

1.8 |

850*600 |

36 |

AS2A1836 |

| 42 |

AS2A1842 |

| 48 |

AS2A1848 |

| 54 |

AS2A1854 |

| 60 |

AS2A1860 |

| 72 |

AS2A1872 |

| 4(100) |

1.58(40) |

2.0 |

1000*600 |

36 |

AS2A2036 |

| 42 |

AS2A2042 |

| 48 |

AS2A1048 |

| 54 |

AS2A2054 |

| 60 |

AS2A2060 |

| 72 |

AS2A2072 |

| 4.8(122) |

1.58(40) |

2.5 |

1250*600 |

36 |

AS2A2536 |

| 42 |

AS2A2542 |

| 48 |

AS2A2548 |

| 54 |

AS2A2554 |

| 60 |

AS2A2560 |

| 72 |

AS2A2572 |

| Ⅲ |

4.8(122) |

1.77(45) |

3.0 |

1700*600 |

42 |

AS3A3042 |

| 48 |

AS3A3048 |

| 54 |

AS3A2054 |

| 60 |

AS3A3060 |

| 66 |

AS3A3066 |

| 72 |

AS3A3072 |

| 6(150) |

1.58(40) |

4.0 |

2250*600 |

42 |

AS3A4042 |

| 48 |

AS3A4048 |

| 54 |

AS3A4054 |

| 60 |

AS3A4060 |

| 66 |

AS3A4066 |

| 72 |

AS3A4072 |

| 6(150) |

1.97(50) |

4.5 |

2250*600 |

42 |

AS3A4542 |

| 48 |

AS3A4548 |

| 54 |

AS3A4554 |

| 60 |

AS3A4560 |

| 66 |

AS3A4566 |

| 72 |

AS3A4572 |

| Ⅳ |

6(150) |

2.36(60) |

6.0 |

3500*600 |

48 |

AS4A6048 |

| 54 |

AS4A6054 |

| 60 |

AS4A6060 |

| 66 |

AS4A6066 |

| 72 |

AS4A6072 |

| 96 |

AS4A6078 |

| 6(150) |

2.56(65) |

7.0 |

4000*600 |

48 |

AS4A6048 |

| 54 |

AS4A6054 |

| 60 |

AS4A6060 |

| 66 |

AS4A6066 |

| 72 |

AS4A6072 |

| 96 |

AS4A6078 |

| 1. Mounting dimensions are conformed to ISO2328; |

|

|

| 2. All forks above have a minimum safety of 3:1; |

| 3. Lock pin assembly included; |

| 4. We can design other forks according to your requirements |

|

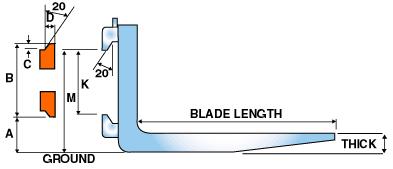

Hook Type Forks

1. Our Forklift Forks are forged with round bar steel or flat iron.

2. Made in accordance with ISO2328-1977, GB5184-85and meets the standard of EN12100-1:2003.

3. Load capacity test: 1 million per time.

4. Material:40Cr;35CrMo.

5. Hook material: 20Cr;35Cr;40Cr, mould forged, high durability and precision.

6. Fully heat treatment to improve hardness as high as 280-320HB.

7. Each single forklift fork has passed the hardness and crack tests (magnetic powder test in a dark room).

8. We are able to manufacture all kinds of forklift forks including: ISO/FEM standard forks, straight forks, blank forks, pin type forks, big section forks, special forks as customer demands.

ISO, I. T. A, FEM standard forks:

2A, 2B, 3A, 3B, 4A, 4B up to 350mm width big forks!

| ISO Standard |

FORKS |

CARRIAGE |

| Class A, B |

M |

K |

A |

B |

C |

D |

| I |

394 |

306 |

76 |

331 |

13 |

16 |

| II |

470 |

382 |

76 |

407 |

13 |

16 |

| III |

568 |

477 |

76 |

508 |

16 |

21.5 |

| IV |

743 |

598 |

127 |

635 |

19 |

25.5 |

| V |

830 |

680 |

127 |

728 |

25 |

34 |

Best Quality comes out from the Best QC process!

1. Raw Material: We strictly pick out the Cr40 Alloy Steel rolled by 6:1 proportion and forged by 3:1 proportion.. Smooth/good shape of raw steel is critically important for final products.

2. Machine/equipment Guarantee 80% equipments are automatically/digital control.

3. Experienced technicians and workers with regular training.

4. ISO 2328 and ISO2330. standard production process with strict 24hours heat-treatment. Hardness testing HB250-361. Strict couple making.

5.3times static overload testing;1.5times dynamic overload testing;1million times of fatigue/yield testing!

6. Market is always the best teacher of quality! Our world wide sale can show the quality confidence!!

Generally, good forks means not only safety but also good fitting and good looking!

Chinese

Chinese USA

USA English

English Russia

Russia